Completely renew and improve the control panel of your Moog Source with

this brand new replacement control panel overlay from Synhouse, with 62

real mechanical switches inside a sandwich assembly based on a flexible

PCB with self-stick adhesive laminated to the underside.

Moog Source membrane panels were garbage from day one and anybody knows

it. A $99 Sanyo microwave oven at Kmart has a better switch panel than a

Moog Source. And in my 41st year of working with electronic music

machines, I have yet to meet a single person who likes membrane switch

panels at all. Membrane switch panels were just a way to avoid paying

for real switches. It's unthinkable that Studio Electronics actually

designed NEW instruments with membrane switches in the 90s...Ugh. No taste.

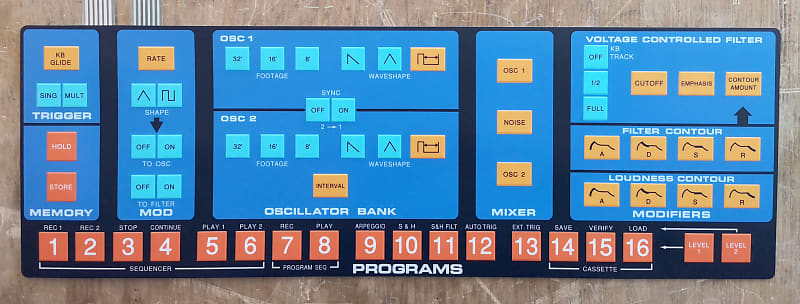

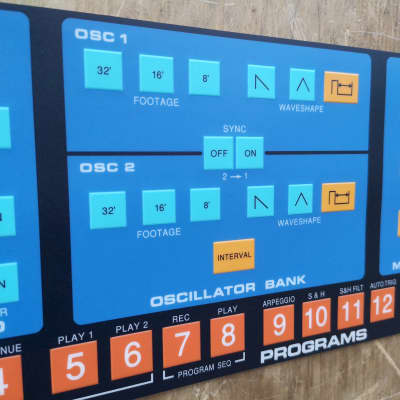

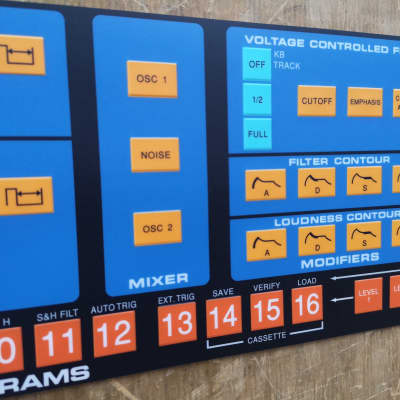

From a slight distance, the new Synhouse switch panel looks like the

same old Moog Source control panel, but up close and from a side angle

you can see that the brightly colored polycarbonate overlay has been

molded (yes, a mold was made for this, Synhouse owns it) with 62 raised

rectangular areas that hide the 62 real snap dome mechanical switches

inside. The switch mechanisms are most similar to those in the switches

of the E-mu Emulator II, SP1200, etc.. The switches move up and down

approximately 2 millimeters. They have positive tactile feedback when

pressed, but it is a muted sound with a low thunk, not loud and clicky

like a VCR switch.

As with all the Synhouse overlay products, it is manufactured of the

highest quality polycarbonate and adhesive with crystal clear printing

and brilliant colors.

-----------------------------------------------------------------------

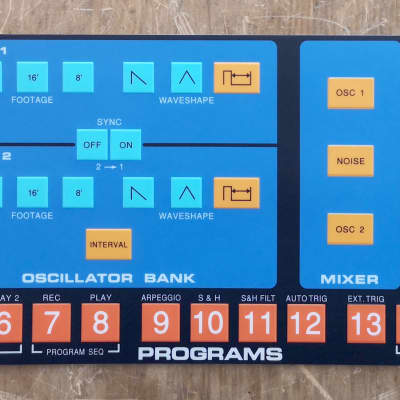

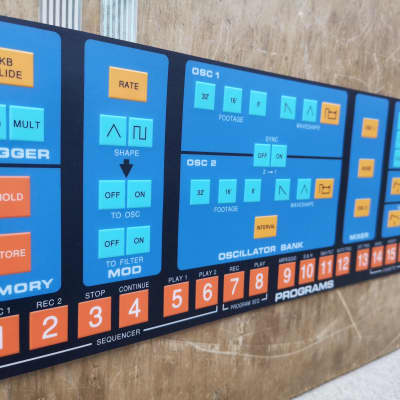

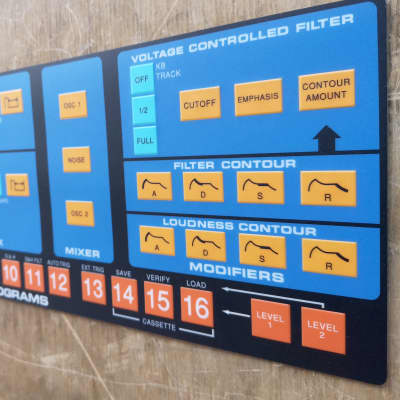

One of the photos shows a 3/4 view of the lower right corner of the

button panel so you can see the buttons are raised. This shows how there

are 62 real mechanical switches inside.

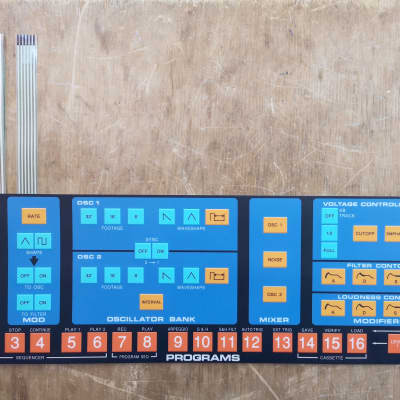

Another photo shows an extreme closeup of the edge of the button panel

so you can see the hybrid mechanical switch/electronic flexible PCB

substrate/six color screen printed polycarbonate overlay sandwich assembly.

The first layer on the bottom is the wax paper backing of the

peel-and-stick 3M industrial adhesive that is to be discarded during

installation. The second layer up is the 3M industrial adhesive itself.

The next layers are the flexible PCB substrates that provide the

circuit/mounting for the switches and three external connector tabs. The

snap dome switches are installed above that. The top layer is the same

high quality molded polycarbonate as all the Synhouse overlays, six

color screen printed with the original Moog Source artwork, printed

underneath so that it can never wear off the top surface, with each

layer bonded by industrial adhesive.

-----------------------------------------------------------------------

Some background:

There are three basic reasons the Moog Source membrane switch panel fails:

1) They are garbage. Just kidding, you know that already. Now to the

real reason #1:

1) Switches fail: The entire membrane switch panel is made of poor

quality materials (as is almost everything inside the Moog Source, MG-1,

etc., as well, from paper phenolic PCBs to the worst IC sockets I've

seen in a lifetime, honestly, I doubt I could find any company in USA

today that could supply such bad quality PCBs and IC sockets) and the

conductive parts have bad connectivity. It looks like it's just silver

spray paint or something being used as the electrical contacts, it's

just pathetic. This leads to many of the switch positions becoming

impossible or almost impossible to activate no matter how hard you try,

then a few years later, more of the switch positions are bad, then more,

and more. While some of them have held up better than others, ALL Moog

Source membrane panels will fail. This was crap that Moog bought from a

crap supplier and it can not be defended. We could walk the junkyards

and landfills and find lots of 35-40 year old microwave ovens that have

been sitting in the rain for 20 years that STILL have membrane switch

panels that work better than the membrane switch panel on a Moog Source.

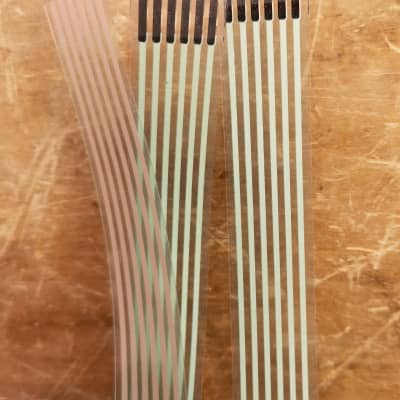

2) The connection to the PCB goes bad: The tips of the three flexible

arms that plug into the connectors on the Source PCB lose their

connectivity. Cleaning them with some chemicals or rubbing carefully

with a pencil eraser can help sometimes, but it also aggravates the main

problem, those tips are paper thin, brittle, and the black carbon

material is shedding off it more and more as time goes on, and it sort

of becomes "tarnished" as well, and the connection goes bad or

intermittent. Just look at them, those dark blue (sometimes green)

ribbons with the silvery lines on them, it's total crap. Then look at

photos number 9, 10, and 11 in this listing. The Synhouse Moog Source

overlay is made of vastly superior materials that doesn't crack like

that, and the tips have better connectivity as well.

This is a fairly well known problem, a lot of us have noticed this when

working on Moog Sources, just how tore up and fragile the tips of the

three flexible arms have become, as we try to plug them back in after

service. However, sometimes when you think #2 is the problem, it's not,

it's actually problem #3 below.

3) While you are trying to figure out why the tips of the three flexible

arms aren't making good enough connection to the connectors on the PCB,

you suddenly realize that the joint area where they come out of the

edge/back of the membrane panel is all cracked at the bend, and THIS is

why it seems to connect sometimes, and sometimes not. This leads to

whole lots of switch positions suddenly becoming dead. That whole flex

assembly is just paper thin and brittle, just appalling. Some of this

isn't just them using cheap materials, it's well known that plastics

have improved greatly over the years, and they couldn't have known a)

the horrible shape it would be in 35+ years later or b) that anyone

would still be using the Moog Source 35+ years later.

4) As a bonus, here's another one: The feel of the old Moog Source

membrane panel is horrible, about as satisfying as pressing a window

with your finger.

That's the main reason I engineered a way to get real switches inside

this new panel.

-----------------------------------------------------------------------

Others:

The Synhouse replacement panel for the Moog Source membrane panel isn't

the first one, just the best. And the only one that isn't still a crappy

membrane panel, having real switches instead.

There have been at least two other sellers making replacement membrane

panels before the Synhouse Moog Source control panel with 62 real

switches came out:

1) Little is known about one of them from at least several years ago,

other than that it was made by one of my out of business ex-competitors

who was getting his account suspended a couple times per year because he

was lying about his location, taking money for big parts orders but not

shipping them, and didn't have a working phone/fax number. His remaining

stock was liquidated to others when he went out of business. In addition

to the main panel, he was also selling the two smaller overlays for the

left side of the Source control panel (one for the Moog wheels and one

for the incremental encoder data wheel), and since those don't

deteriorate nearly as badly as the main membrane panel, people rarely

bought them (observing that is why I put the big money into this new

mechanical switches panel and didn't go to great lengths and expense to

make those two smaller overlays that people would rarely want, I may

still make them someday but it's a low priority here). Since few people

wanted to buy them, those two smaller overlays have been sold and resold

by multiple online sellers who still have his unsold old stock.

2) The second one is more recent, and is sold with the claims, "Limited

quantity. The appearance is exactly the same as the originals. The parts

known to become defective on the original membrane have been improved in

an invisible way."

Wow, I don't know where to start debunking that joke introduction...

Let's start with "Limited quantity", this is yet another overlay seller

using this tactic to sell overlays faster than the market wants to buy

them. I deal with this all around my business, I've got another guy who

has spent almost five years selling his one and only overlay design that

he keeps making again and again in the same defective design using "LAST

ONES!", "RARE!", "CLOSEOUT", "SELLING AT COST!", "BLOWOUT SALE !!", and

"WON'T BE MADE AGAIN!" as the sales pitch. When someone is manufacturing

an overlay, the quantity is "limited" to however many they choose to

manufacture. This shouldn't be a reason to buy one now if you don't want

one now, don't need one now, or don't have the money now. The Synhouse

overlays are factory made in big quantities, stocked in big quantities,

and will be produced again in big quantities when sold out, so there is

no need to buy a lot of them because you worry I won't be here, I WILL

be here, and I've been here, twenty-two years and counting.

As for "The appearance is exactly the same as the originals.", no, it

isn't. All the lettering/font styles are WRONG.

The Source was designed with a futuristic sort of look (probably part of

why they used a membrane panel for the first time ever), and the

lettering/font style is one of rounded squares, or flattened ovals if

you prefer to say it that way.

Look at your old Source panel where it says "OSC 1" The O and C are more

square than round, but this "Moog Source Membrane Panel" replacement has

an O and a C that are just about completely round. This isn't even a

font "style", it's just whatever plain old letters their art software had.

For the Synhouse overlays, the old letter fonts are almost never

available, nor is there anything new that is the same, and "similar"

isn't similar enough for me, so we have to create our own. It takes time

and money, but that (almost) always comes back with the selling price

that only a flawless product can command.

Then look on the left at "TRIGGER", the "Moog Source Membrane Panel"

replacement has ridiculous huge Gs that are like circles, and skinny Rs

that lack the flat areas. It's the same with all the other words on it,

it's just that those on the top and left are the ones that immediately

stuck out to me the first time I saw it. This problem is made worse

again by having all of those words (TRIGGER, MEMORY, etc.) too bold with

the letters too thick. And the giant word in the bottom center is the

worst, "PROGRAMS", the round S and the big round O and G just make it

look silly, a whole different word. The artwork on this one is a failure.

Then it says, "The parts known to become defective on the original

membrane have been improved in an invisible way." Invisible, eh? Maybe

an invisible man would understand this, but it's nonsense to any

thinking person.

-----------------------------------------------------------------------

Installation:

No matter how flexible it may seem, DO NOT BEND THE NEW SWITCH PANEL.

BEFORE removing old membrane panel and BEFORE peeling the backing off

the rear adhesive of the new one, open the Moog Source and connect the

new control panel to the connectors on the Moog Source PCB.

With something flat and solid behind the new one to hold it solidly so

you can press the switches and to be sure you don't bend it (like the

control panel area of the Moog Source itself, or a hard counter top,

etc.), test each switch (powered up with sound) to be sure everything is

working perfectly. You can't just squeeze it between your fingers, as

you shouldn't press on the underside like that, it's the areas around

the switches that support them, pressing from the bottom could damage

the substrate or connections.

Once all is confirmed, remove the old one and stick the new one in place

WITHOUT BENDING IT!

-----------------------------------------------------------------------

About Synhouse synthesizer and drum machine overlays:

The construction details and quality of the Synhouse synthesizer and

drum machine overlays don't come easily; It requires multimillion-dollar

factories with automation and properly trained operators, and tens of

thousands of square feet of large-scale equipment. Any factory that

knows what they are doing and is properly automated and equipped is not

going to take an order for 10 stickers. Get serious. That wouldn't pay

for the time to set up the materials and equipment, much less the

materials themselves, the downtime of the equipment, or the tooling

cost. It wouldn't even pay for the wasted 2-part epoxy ink that is lost

during every production run setup and subsequent cleanup. I learned this

sort of thing the hard way 20 years ago. As such, I did what was needed

and more than 20 years ago I was making a robotically assembled

electronic product and shipping it to customers in 39 countries around

the world.

Synhouse has made a substantial investment to get into the production of

synthesizer and drum machine overlays and it shows in the construction

details (seamless textured LED windows on the SP1200 overlay, smooth

clear windows over the LCD on SP-12 [instead of a lie about how SP-12s

are not supposed to have a clear window over the LCD---when you know

very well that your SP-12 and every SP-12 you've ever seen in your life

had a clear window over the LCD, it's one of the top reasons people buy

the Synhouse SP-12 overlay with the clear LCD window, because the old

one was dented, scratched, perforated, kinked, or yellowed], and smooth

clear windows over the LCD on Emulator II overlays) and quality (2-part

epoxy screen print inks, different textures of polycarbonate substrate

materials, high strength peel and stick adhesive backings) and this

company will continue to prove itself over time with very, very high

quality goods shipped worldwide consistently for 21 years and counting.

You can buy this product here and now or you can wait and buy it one

year from today, your choice. It depends on when YOU want it, not on the

instability of the joker trying to sell it.

-----------------------------------------------------------------------

About the garbage synthesizer and drum machine overlays sold by others

and in the past (or even here and there today if they can find buyers):

Some of those guys made overlays that were relatively high quality in

materials, but with wrong construction details, wrong colors, bad fit,

and horrible dimensional linearity (this means that colored sections,

borders, and text are in the wrong locations with a few millimeters of

error in many places, and the die cut cutout location relative to the

graphics printing is wrong and varies from one piece to another,

something that should not happen in any manufactured product, because

it's indicative of low quality manufacturing practices and trying to do

things by hand measuring or by eyeballing it, instead of by

computer-controlled automated equipment with the standard CNC machine

accuracy that the Synhouse overlays have on EVERY piece (no matter how

many you compare over any number of years), and the next production run

is exactly the same because it's a computer running a computer file on

automated screen printing equipment with precise computer control of

stroke speed, squeegee pressure, and all other parameters, things that

will be 30% different on every piece coming out of the T-shirt

shop-style operations that everyone else has been using---I mean the

BEST of the bad ones have been using T-shirt shop-style operations, the

worst of the bad ones aren't even doing that, they are using inkjet

computer printers instead of using multiple silkscreens and screen

printing one color at a time, and some without even cutting them out

after printing, instead telling you to use a knife to cut out 67 holes

for buttons, sliders, pots, LCD and LEDs by hand, so that your SP1200

ends up looking like the school project of a slow kid). Some of the

better ones of the bad were relatively accurate in type styles and other

cosmetic details, but with low quality or incorrect materials and

printing, wrong colors, and wrong construction details as well. Some of

them were just totally shameful garbage.

Synhouse Multimedia Corporation has been in business for 21 years and

has been manufacturing from day one. Synhouse existed for 4 years

informally before incorporation, and was only officially incorporated in

1999 when a huge amount of expense was going to be incurred in

manufacturing the first products, to ensure that the investment and

expense of the startup could be deducted and written down over the

course of many years, because there was no possibility of making money

in the first year of business. Over twenty years later, those first

products are still being manufactured.

Reverb Buyer Protection

Reverb has your back if your item is lost, damaged, or doesn't match its description. Simply report any issues within 7 days and we'll help you get a full refund.Learn more about Reverb Buyer Protection.

| Condition | Brand New (New) Brand New items are sold by an authorized dealer or original builder and include all original packaging.Learn more |

| Brand | |

| Model |

|

| Categories |